Since the end of 2015, two construction cranes over one hundred meters high on the striking, star-shaped BayWa high-rise have made it clear that something is happening here. They are the unmistakable symbol of the general renovation taking place there. The building at Arabella Park, which dates from the 1970s, was getting on in years. At the same time, new space was to be created to meet the growing demand for more room. Consequently, the plan provides for modernization, adding levels and expansion. In the course of this work, the structure will become taller, slimmer and visually lighter. The star-shaped main building gains around 7,000 square meters of new office space. This will be complemented by a separate four-story campus building with an additional 5,500 square meters of space. Andreas Helber, CFO of BayWa AG and board member responsible for real estate, estimates that the investment will be in the lower three-digit million range.

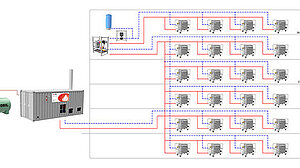

In order for the extensive construction work to be completed in September 2017 as planned, work on the gutted main building also had to be carried out over the cold winter months. Once the temperatures had dropped below zero, winter construction heating became inevitable. Waldemar Cibis, Plant Construction Team Leader at Rudolf Otto Meyer Technik Ltd. & Co. KG (ROM technology) in Munich was responsible for taking care of this task, among other things. Rud. Otto Meyer Technik Ltd. & Co. KG specializes in the planning and installation of building services. Around 2,300 employees work for the company. These are divided into four business areas: Service & Facility Management, Electrical, Mechanical and Building Automation. The name ROM Technik goes back to the company founded in 1858 by Rudolph Otto Meyer (1825-1899). ROM Technik offers its customers throughout Germany the entire spectrum of building services engineering from a single source, as in the case of the BayWa headquarters. Since the team leader had good experience with the rental specialist Hotmobil from previous projects, he ordered 20 mobile electric fans with 15 kW each from them as a first immediate measure. It soon became clear that although these were ideal for selective use, they were not sufficient for temperature control of a 21-story, 71-meter-high building. That's why he developed a complete solution together with Hotmobil consultant Matthias Brinkmann. It comprises a heating container with an output of 2.5 megawatts placed adjacent to the building. The oil supply is provided by a heating oil tank which is connected to the container. The mobile tank with a volume of approx. 10,000 liters is also from the Hotmobil rental fleet. Four water fed mobile fan heaters supplying an output of 20 kW each for pleasant working and efficient drying temperatures were placed on each floor. With a total of 21 floors and two basement levels, a total of 92 mobile ventilation units were used. A total of eight kilometers of connecting pipes from the individual floors to the fan heaters were professionally connected by the experts of the ROM Technik team. The two main lines from the heating container to the high-rise building and the vertical black steel ascending pipes with a dimension of DN 125 also were installed by the ROM technicians. Due to its static height, the 71 meter high BayWa Company Headquarters building has a system pressure of 7.1 bar. The boiler in the mobile heating container reaches its limits at a maximum system pressure of 6 bar. It therefore was necessary to install a system separation in the 15th story comprising a plate heat exchanger, a pump and an expansion tank (see Figure 1). The two lower levels do not affect the pressure, because the fans are located below the boiler level. A malfunction alarm which immediately reports any error messages to the responsible service engineer's cell phone, thus enabling a fast response, ensures fault-free operation of the mobile heating concept. Another strong argument in favor of this water fed heating concept for winter construction heating is the energy and cost savings of more than 50 percent that it also yields in comparison to conventional direct-fired air heaters.

In February, team leader Waldemar Cibis summed it all up by saying: "I feel like I have been well advised by Hotmobil and am very satisfied with their cooperation with us and with the performance of the mobile heating concept". This temporary heating concept remained in use until mid April 2017 and also contributed to meeting the construction schedule.